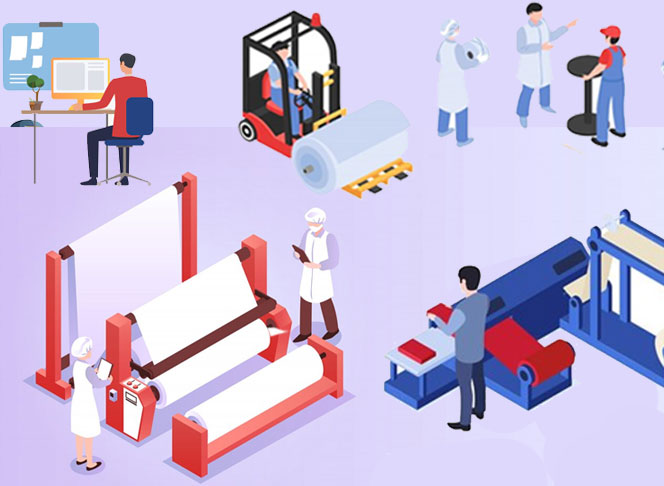

PROCESS MANAGEMENT MODULE unifying the business processes to provide the central database. This specific kind of module also assists in optimizing the production processes to ensure the delivery of quality products on time.

Automating the process of identifying potential suppliers, negotiating price, sending purchase order to the supplier, and billing, the module streamlines the process of procurement of required raw materials.

This module in ERP will ease the financial management across the whole system. With the help of the financial management module, you can easily track the cash flow, account payables, and receivables procedures.

Plan and track your production in your ERP to optimize supply chain efficiency and ensure product quality. Manage work orders, track production times, and ensure timely delivery to meet the requirements of customers.

ERP sales modules is one of the most essential elements of a business since it helps handle all business activities for export/ domestic sales of an organization. The customer, as well as product databases, are stored and well-maintained in the ERP sales modules.

Inventory is always considered to be an important business element that prevents business from falling down. It empowers business manage its product or asset inventory without facing many hurdles.Which cuts down your process times, bring down your stock levels, automate transactions, and gives complete traceability on all operations.

Cut, Make, and Trim (CMT) production is a process where garment manufacturers receive pre-designed fabrics & specifications from clients& then handle cutting, stitching& finishing the garments. Subcontracting is a common practice in the garment industry where specific stages of production, such as embroidery or printing, are outsourced to specialized vendors. Cutting production is the initial phase of garment manufacturing where fabric is precisely cut into various pattern pieces based on the design & size specifications.

A Cutting Management Module in a garments ERP system is essential for managing the cutting process in the apparel production workflow. This module helps ensure efficiency, minimizes waste, and tracks inventory usage.

Optimise resource utilization by effectively allocating labour, equipment, and materials based on project requirements and availability. Ensure seamless onboarding, timely payments, and regular appraisals to foster a happier, more content and productive workforce

Ensure seamless onboarding, timely payments, and regular appraisals to foster a happier, more content and productive workforce. Enable organizations to replace manual HR methods with AUTOMATED processes.

The construction industry faces complexity in project scheduling and its cascading effect when the schedule changes. Track metrics and schedule maintenance proactively to reduce downtime, boost performance, and extend lifespan

Track, monitor, and manage purchase, warranty, insurance, and maintenance details of all physical assets in one place. From tracking asset locations and depreciation to scheduling maintenance and monitoring usage.